Understanding Hydraulic Ball Valves: The Backbone of Fluid Control

When it comes to the efficient operation of fluid control systems, few components play as crucial a role as the hydraulic ball valve. This article delves into the intricacies and significance of hydraulic ball valves, examining their construction, operation, applications, and benefits that make them indispensable in various sectors.

What is a Hydraulic Ball Valve?

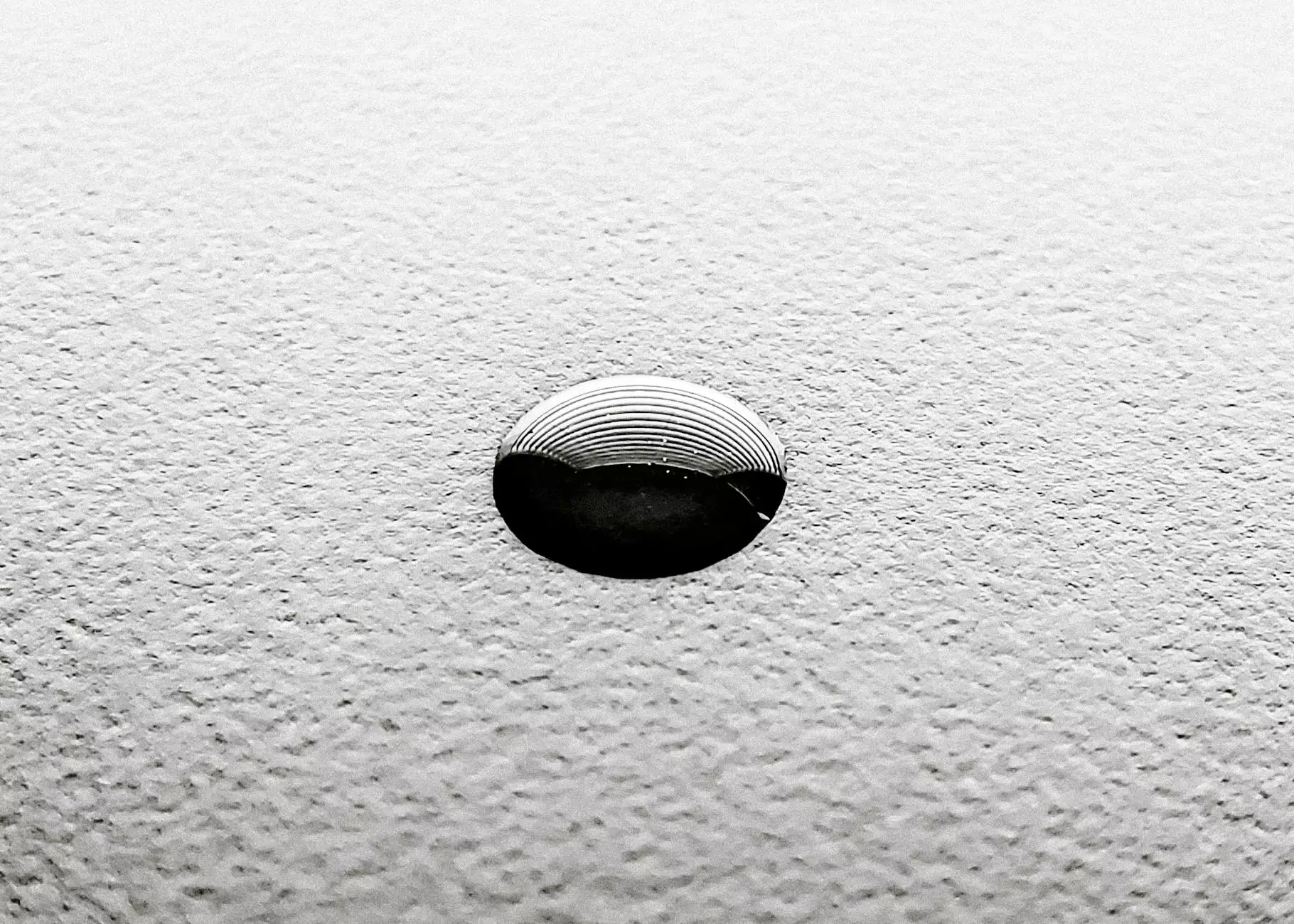

A hydraulic ball valve is a type of quarter-turn valve that uses a spherical disc (the ball) to control the flow of liquid or gas through a pipeline. The ball has a hole or port that, when aligned with the flow, allows fluid to pass through. When the ball is rotated 90 degrees, the port is perpendicular to the flow, effectively sealing off the passage.

Construction of Hydraulic Ball Valves

The construction of hydraulic ball valves is a key factor in their effectiveness. Typically, they consist of the following components:

- Ball: The core object made from materials such as stainless steel or plastic, designed for durability and corrosion resistance.

- Body: Made from robust materials, the body houses the ball and is designed to withstand high pressures.

- Seats: These ensure a tight seal when the valve is closed, typically made from resilient materials like PTFE.

- Stem: The component that connects the handle or actuator to the ball, enabling the valve to be turned.

- Actuator: In many systems, this enables remote or automated operation of the valve, either through electrical, pneumatic, or hydraulic means.

Types of Hydraulic Ball Valves

Hydraulic ball valves come in several styles, each suited for specific applications:

- Two-Way Ball Valves: Simple on/off control for fluid flow.

- Three-Way Ball Valves: Direct flow between two paths or mix fluids.

- Trunnion Mounted Ball Valves: Designed for higher pressure applications, with increased stability and control.

- Floating Ball Valves: The ball is positioned by the pressure of the flow, commonly used for lower pressure applications.

How Hydraulic Ball Valves Work

The operation of hydraulic ball valves is straightforward yet efficient. When the valve is open, the ball rotates to align the flow path with the pipeline. This design minimizes pressure drop and ensures a smooth flow. Conversely, closing the valve involves rotating the ball to block the flow completely. The quick quarter-turn mechanism enhances process control and allows rapid shut-off in emergencies.

Advantages of Using Hydraulic Ball Valves

The benefits of hydraulic ball valves extend across numerous industries:

- Durability: Constructed from heavy-duty materials, they can handle high pressure and harsh environments.

- Low Operating Torque: Requires minimal effort to operate, making them easy to handle and manage.

- Quick and Clear Operation: The quarter-turn mechanism allows for fast opening and closing, crucial in critical applications.

- Leak-Free Design: High-quality seals and ball design ensure minimal leakage, vital for safety and conservation.

- Versatility: Efficient in various applications, from water supply to oil and gas sectors.

Applications of Hydraulic Ball Valves

Hydraulic ball valves are utilized across diverse industries:

- Water Treatment: Control water flow in purification and distribution systems.

- Oil and Gas: Manage and direct the flow of hydrocarbons in pipelines.

- Chemical Processing: Control aggressive chemicals efficiently and safely.

- HVAC Systems: Regulate the flow of water in heating and cooling applications.

- Food and Beverage: Ensure sanitary flow control in processing plants.

Choosing the Right Hydraulic Ball Valve

Selecting the appropriate hydraulic ball valve for your specific needs requires careful consideration of several factors:

- Pressure Rating: Ensure the valve can withstand the operational pressure of your system.

- Size: Match the valve size to your pipeline for optimal performance.

- Material: Choose materials that resist corrosion and withstand the fluids being handled.

- End Connections: Assess compatibility with existing piping systems.

Maintenance of Hydraulic Ball Valves

Proper maintenance is critical to ensure the longevity and reliability of hydraulic ball valves. Basic maintenance protocols include:

- Regular Inspections: Check for wear and tear, leaks, and overall integrity.

- Lubrication: Ensure the stem and sealing surfaces are adequately lubricated to prevent sticking.

- Cleaning: Keep valves free from debris and build-up that may affect performance.

- Testing: Conduct routine functional tests to verify operability and safety.

Conclusion

The hydraulic ball valve is an essential component in a myriad of industrial applications, providing robust, reliable, and efficient fluid control. Understanding their construction, types, advantages, and proper maintenance can empower industries to optimize their operations while ensuring safety and compliance. It is crucial for businesses, like those found on fitsch.cn, to choose high-quality hydraulic ball valves that guarantee performance and longevity in their fluid systems.

With the ever-evolving industrial landscape, staying informed about the latest technology and innovations in hydraulic ball valves will allow you to remain competitive, efficient, and capable of meeting the demands of modern fluid control systems.